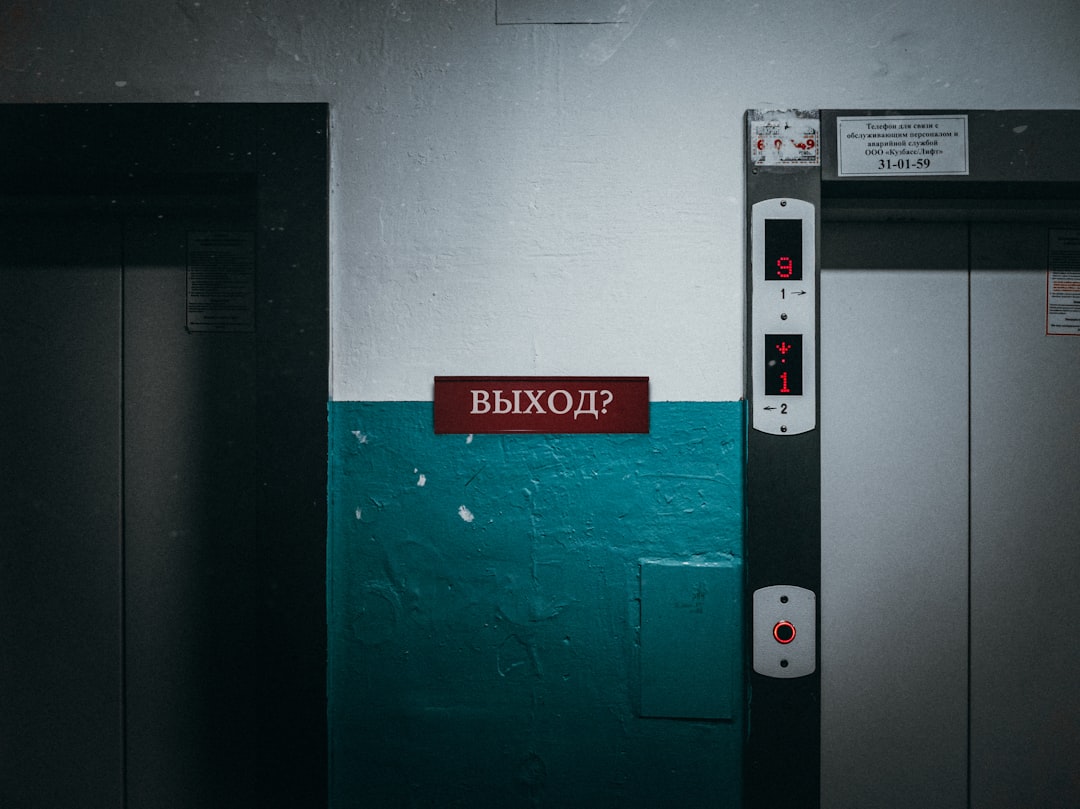

Electric Motors in Elevators: Keeping Vertical Transportation Efficient

Introduction

Electric motors play a crucial role in the efficient operation of elevators, ensuring smooth and reliable vertical transportation. As buildings continue to reach new heights, the demand for efficient elevator systems becomes increasingly important. In this blog post, we will explore the significance of electric motors in elevators and how they contribute to keeping vertical transportation efficient.

The Role of Electric Motors in Elevators

Electric motors are the heart of elevator systems, responsible for converting electrical energy into mechanical energy to power the movement of the elevator car. These motors provide the necessary force to lift and lower the car, ensuring safe and efficient transportation between floors.

Types of Electric Motors Used in Elevators

There are two main types of electric motors commonly used in elevators:

- AC Motors: Alternating current (AC) motors are widely used in elevator systems. They offer excellent torque control, making them ideal for smooth and precise movements. AC motors are known for their energy efficiency and reliability.

- DC Motors: Direct current (DC) motors were commonly used in older elevator systems. While they are less common today, some older buildings still rely on DC motors. These motors provide a simpler control system and can handle heavy loads.

Efficiency and Energy Savings

Efficiency is a key factor in elevator design, and electric motors play a significant role in achieving this. Modern elevator systems utilize advanced motor technologies to optimize energy consumption and reduce operating costs.

Gearless Traction Systems

One notable advancement in elevator motor technology is the introduction of gearless traction systems. These systems eliminate the need for bulky gears, resulting in smoother and more efficient operation. Gearless motors offer higher energy efficiency and require less maintenance compared to traditional geared systems.

Regenerative Braking

Another way electric motors contribute to efficiency is through regenerative braking. When the elevator car descends, the motor acts as a generator, converting the excess energy into electrical power. This power is then fed back into the building’s electrical grid, reducing energy consumption and saving costs.

Variable Frequency Drives

Variable Frequency Drives (VFDs) are commonly used in modern elevator systems. These drives allow for precise control of motor speed and torque, resulting in smoother and more efficient operation. VFDs also help reduce energy consumption by adjusting the motor’s power output based on the load requirements.

Maintenance and Reliability

Electric motors used in elevators require regular maintenance to ensure optimal performance and reliability. Routine inspections, lubrication, and testing are essential to identify and address any potential issues before they lead to breakdowns or malfunctions.

Remote Monitoring and Predictive Maintenance

Advancements in technology have enabled remote monitoring and predictive maintenance for elevator systems. By collecting real-time data from sensors embedded in the motor, technicians can identify potential problems and schedule maintenance proactively. This approach minimizes downtime, reduces repair costs, and enhances overall system reliability.

Conclusion

Electric motors are the backbone of efficient elevator systems, ensuring smooth vertical transportation in buildings of all sizes. From gearless traction systems to regenerative braking and variable frequency drives, these motors contribute to energy savings, reliability, and improved passenger experience. By embracing the latest motor technologies and investing in regular maintenance, building owners can optimize elevator performance and keep vertical transportation efficient for years to come.